Dispensing Equipment

Dymax manual and automated fluid dispense systems and spray valves are easily integrated into existing manufacturing processes for easy application of coatings, lubricants, or masking resins.

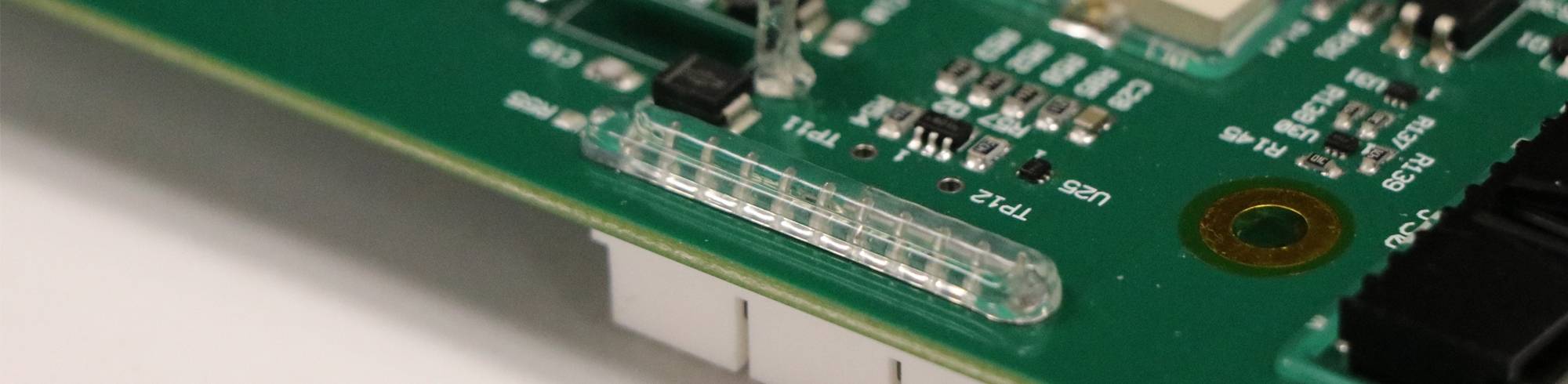

Dymax light-curable encapsulants offer electronic protection for bare die, wire bonds, chip-on-board, and integrated circuits. Upon exposure to UV or LED light our printed-circuit board (PCB) encapsulants cure tack-free in seconds and offer superior protection on both flexible and rigid PCB platforms.

Secondary curing mechanisms are available in some Dymax products to address shadow areas. Dymax dual-cure materials cure upon exposure to light and feature a secondary ambient moisture cure capability. Dymax Multi-Cure® materials cure upon exposure to light and offer a secondary heat cure capability.

Electronic Encapsulation Applications Include:

Dymax 9000-series encapsulants cure tack-free in seconds upon exposure to UV/Visible light for superior protection of components on both flexible and rigid printed circuit board platforms. They are ideal for chip on board, flex, and glass, glob tops, bare die, integrated circuits, and wire tacking and bonding.

Product Number

Product Description

Regional Availability

Product Number

Product Description

Regional Availability

Use our formulated product finder to help you find the right material. Interested in learning more or have questions? Contact Us, we want to hear from you.