- Cures with UV/Visible light

- See Cure - dispenses blue, cures clear

- No solvents added

- Halogen free

- Tack-free surface after cure

- Compatible with needle or jet dispensing equipment

- Highly thixotropic for minimal movement after dispense

- Reduces stress on board components

- Adheres to various PCB substrates

Reinforcement Adhesive

9309-SC

Edgebond / CSP Reinforcement Adhesive

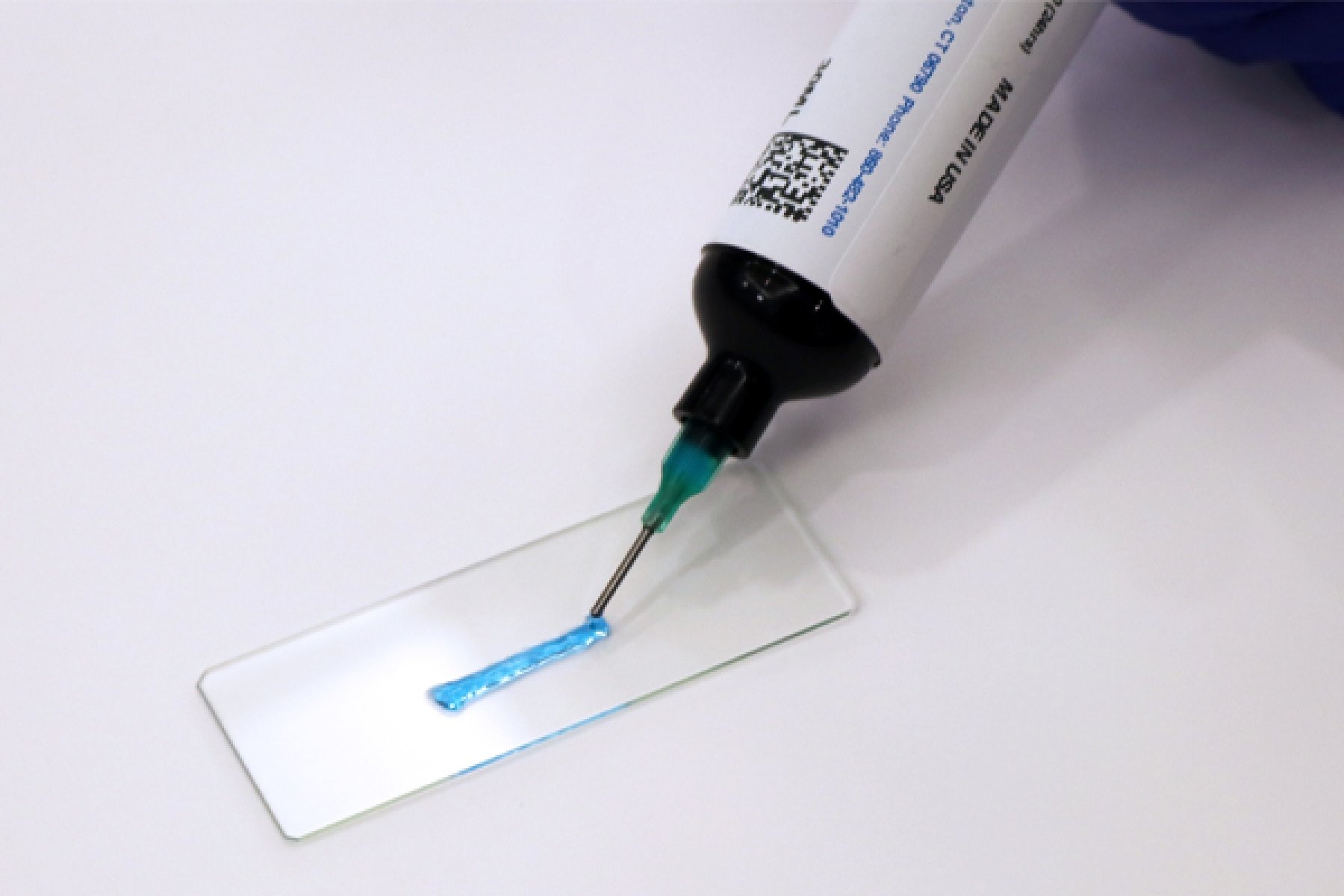

Dymax 9309-SC adhesive cures upon exposure to UV/Visible light to quickly ruggedize circuit board components. This edgebond material is ideal for applications where shock attenuation or ruggedization is necessary. The material provides rapid bonding to leadframe, PCB, silicon, and ceramic. The product is ideal for reinforcement of fine-pitch leads or leadless components on printed circuit boards as well as an alternative to underfill. This adhesive is compatible with both needle and jet dispensing systems and is highly thixotropic, minimizing movement after dispense.

9309-SC adhesive is formulated with See-Cure color-change technology, making it appear bright blue in the uncured state and very visible when dispensed onto substrates. The color changes from blue to colorless when exposed to sufficient light energy, providing visual confirmation of full cure.

Dymax materials have no solvents added and cure upon exposure to light. Their ability to cure in seconds results in lower processing costs. When cured with Dymax UV light curing spot lamps, focused beam lamps, flood lamps, or conveyor systems they deliver optimum speed and performance for maximum efficiency. Dymax lamps offer the optimum balance of UV and visible light for the fastest, deepest cures.

This product is in full compliance with the RoHS2 Directives 2015/863/EU.

Features

Typical Properties

Looking for additional technical specifications. Download a Product Datasheet in our Resource Library or talk with our technical experts.

Get in touch| Property | Values |

|---|---|

| Viscosity (nominal) | 45,000 cP |

| Uncured appearance | Blue transparent gel |

| Recommended substrates | Lead frame; ceramic; PCB; silicon |

Looking for additional technical specifications. Download a Product Datasheet in our Resource Library or talk with our technical experts.

Get in touchResources

Request a Quote

Ready to take the next step? Dymax team member will get back to you shortly.

9309-SC Ruggedization Material for Printed Circuit Boards

Dymax Application Engineers support all your technical requirements.

Our technical experts are ready to answer any product or application questions you may have

Find your solution