Dispensing Equipment

Dymax manual and automated fluid dispense systems and spray valves are easily integrated into existing manufacturing processes for easy application of coatings, lubricants, or masking resins.

In-vitro diagnostic tests are known to use substrates such as COC/COP thermoplastics or glass that are extremely difficult to bond. Dymax line of medical UV adhesives allows for an easier bond by using light to cure the adhesive. Once the adhesive is applied, the manufacturer has unlimited time to adjust the parts. Then, the adhesive can be cured in seconds when exposed to UV/visible light.

Additionally, some formulations utilize Dymax patented technologies See-Cure or Ultra-Red® fluorescing. Encompass® technology products are also available, introducing LED optimized materials combining See-Cure and Ultra-Red fluorescing technologies into one product for easy visual verification of material placement, cure, and quality inspection.

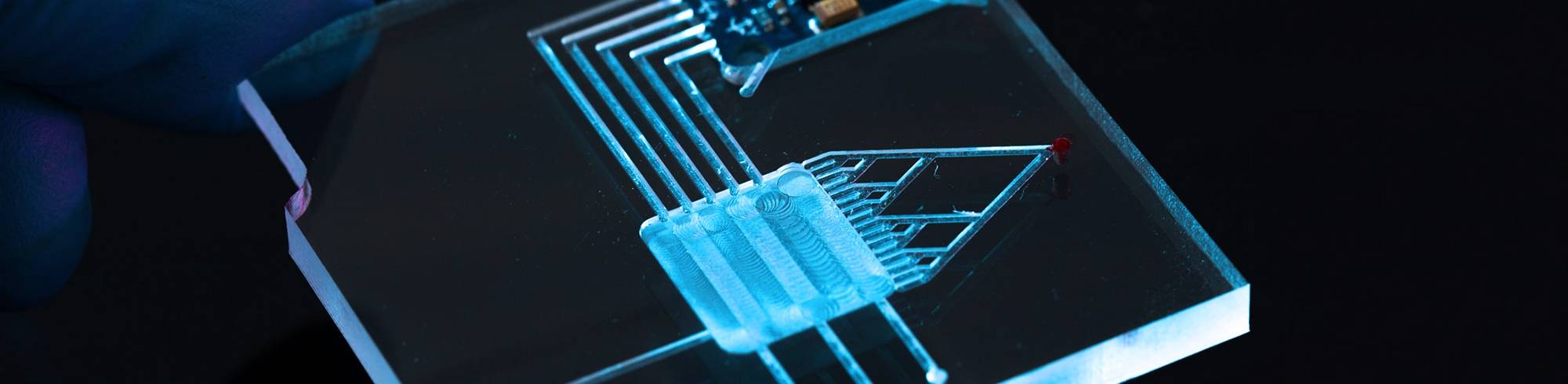

Assembly processes include the manufacturing of diagnostic slides, microplates, silicon wafers, or lab on a chip device, which are used in many medical applications such as blood or tissue testing. You can trust that Dymax adhesives will help manufacture a high-quality product others can depend on.

Product Number

Product Description

Regional Availability

Product Number

Product Description

Regional Availability

Use our formulated product finder to help you find the right material. Interested in learning more or have questions? Contact Us, we want to hear from you.