- Fast cure with LED or UV light

- No solvents added

- Fluoresces blue under black lights

- Multi-Cure - secondary heat cure

- Impact resistant

- Compliant with ISO 10993

MD® Medical Adhesive with Multi-Cure®

1128A-M

Medical Adhesive for Plastic and Metals with Secondary Heat Cure Capability

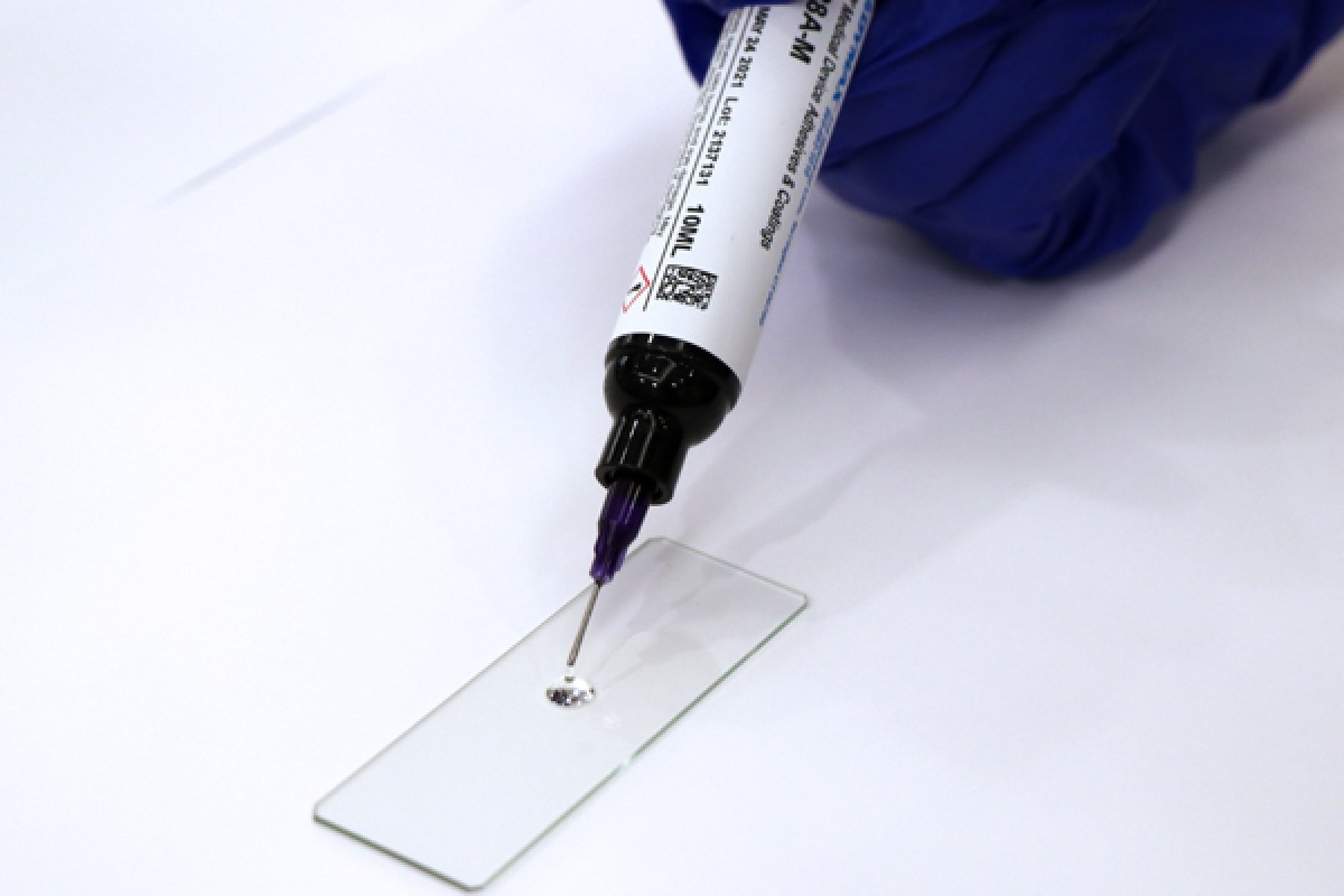

Curing in seconds upon exposure to UV or LED light, MD® 1128A-M medical device adhesive features Multi-Cure® a secondary heat cure for shadow areas. The product bonds metals and plastics typically used in the manufacture of medical devices. This impact-resistant material also fluoresces blue for in-line inspection under low-intensity black light (365 nm). Bondable substrates include stainless steel, aluminum, glass, ABS, PA, PU, as well as nickel-titanium. 1128A-M meets a variety of ISO 10993 biocompatibility approvals. Typical applications include metal bonding, needle bonding, and heat exchanger assembly.

Dymax MD® Medical Device adhesives have no solvents added and cure upon exposure to light. Their ability to cure in seconds enables faster processing, greater output, and lower processing costs. When cured with Dymax light-curing spot lamps, focused beam lamps, flood lamps, or conveyor systems they deliver optimum speed and performance for medical device assembly. Dymax lamps offer the optimum balance of UV and visible light for the fastest, deepest cures.

MD® 1128A-M medical device adhesive is in full compliance with the RoHS2 Directives 2015/863/EU.

Features

Typical Properties

Looking for additional technical specifications. Download a Product Datasheet in our Resource Library or talk with our technical experts.

Get in touch| Property | Values |

|---|---|

| Viscosity (nominal) | 600 cP |

| Cured durometer hardness | D80 |

| Cured elongation at Break | 13% |

| Recommended Substrates | Stainless Steel; Aluminum; Nickel Titanium; Glass; ABS; PA; PU |

Looking for additional technical specifications. Download a Product Datasheet in our Resource Library or talk with our technical experts.

Get in touchRequest a Quote

Ready to take the next step? Dymax team member will get back to you shortly.

Dymax Application Engineers support all your technical requirements.

Our technical experts are ready to answer any product or application questions you may have

Find your solution