Bonding Catheter Substrates

The substrates utilized in today’s catheter designs, such as PEBA and Nylon 12, are often difficult to bond to. If components do not adhere properly, failure of the finished device can occur. To avoid this from happening, medical device engineers are vested in finding adhesives that meet stringent testing criteria including excellent performance in pull strength, peel strength, burst pressure, and accelerated aging.

Millions of catheters from indwelling to intermittent to external are used each year to treat a variety of medical conditions including neurogenic bladder, UTIs, and spinal cord injuries. When used daily, the importance of having a dependable catheter assembly is not lost on engineers, medical personnel, or patients. A catheter not only needs to withstand the constant force of insertion and removal and not degrade over time but also be biocompatible to prevent irritation or potential infection. Some of the applications associated with catheter manufacturing include renal denervation, balloon bonding, vascular intervention, marker bands, and manifold bond joints. That is why pull strength and aging performance are critical to the overall catheter design.

The Dymax 215-CTH-UR-SC series of adhesives was developed to address the issues of reliable joining of hard-to-bond-to catheter substrates and aging concerns. The adhesives cure “on-demand” in seconds upon exposure to UV/Visible light and are also LED optimized. Other desirable features of this product line include:

• No solvents added

• Biocompatibility

• Adherence to a variety of plastic substrates

• One-component, no mixing

• ISO 10993 certified

• Compatible with EtO, gamma, and E-Beam sterilization

• Encompass® technology for visual confirmation of adhesive placement and cure and post-cure fluorescing for inspection

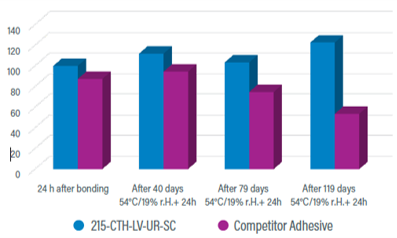

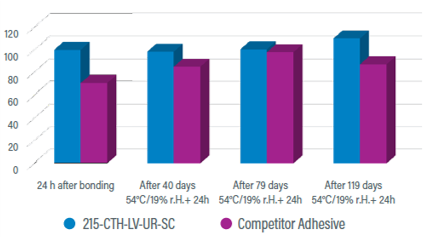

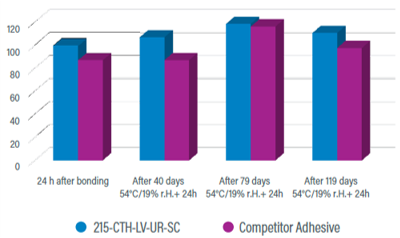

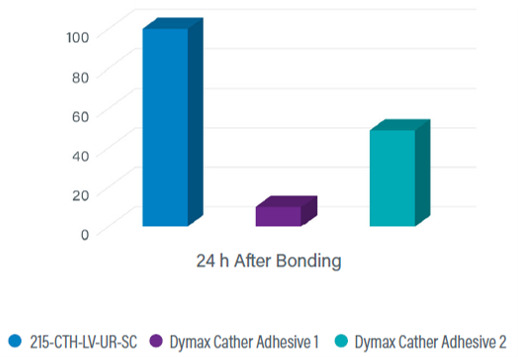

A benchmarking study was completed on five pairs of tube-to-connector assemblies using different substrate combinations along with 215-CTH-LV-UR-SC versus a competitive material. The pull test was done using a Zwick Tensile Testing Machine and the results show that the Dymax adhesive was 10%-30% stronger than a top competitor. The charts below provide a glimpse into the complete details.

PEBAX 55D Tube-PC Connector

PEBAX 72D Tube-PC Connector

TPE Tube-PVC Connector

In the aging performance part of the study, 215-CTH-UR-SC was subjected to 54°C Dry Heat Accelerated Aging, and held its bond strength even after three years versus a Dymax legacy product. The table below shows the results. Additional aging charts can be found in the product selling guide listed below.

For manufacturers seeking a catheter adhesive that meets critical performance standards for strength and aging, the Dymax 215-CTH-US-SC series may be a good choice for their specific application.

Unlock the full details of this study by downloading our selling guide.

_________________________________________________________

Enjoying This Content? Let’s Stay Connected.

If you’re finding value in our insights, why not get more of it—delivered right to your inbox? Subscribe to receive the latest technical articles, white papers, product news, and expert tips.