Choose the Masking Application Method Suitable for Your Surface Finishing Process

Manufacturers that utilize wax, tape, or lacquer masking application methods to protect their components from harsh surface finishing processes like grit blasting, acid stripping, plating, and anodizing know how imprecise and time-consuming they can be. Some methods require hand application, and some are solvent-based, which can slow down throughput and increase scrap and rework.

SpeedMask® products are quickly applied in one layer, cured with UV/Visible light in seconds, and easily removed through incineration or peeling. They provide an alternative to labor-intensive application techniques and superior protection during surface treatment processing. In addition to the benefits of fast application, improved speed, and simple removal, SpeedMask maskants are one-component and have no solvents added, making them an eco-friendly choice for businesses striving to meet green initiatives. Many SpeedMask products are also 100% organic materials.

Before deciding to use a SpeedMask maskant, it’s important to know how to apply it to achieve the best outcome.

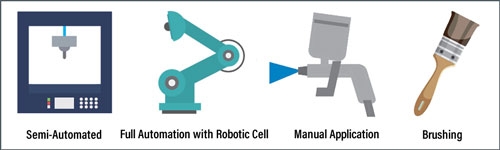

Semi-Automated Application

A semi-automated process uses machines (XYZ systems) programmed to follow exact specifications and designs to dispense maskants precisely onto components. This method helps to mitigate human error and provides consistent material coverage to meet rigorous quality requirements.

- Designed for repeatability and accuracy

- Suited for medium-volume applications

- Incorporate into in-line operations with curing

- Flat surfaces, including printed circuit boards

Full Automation with Robotic Cell Application

The full automation with robotic cell system is used for high-volume precision manufacturing that may require quick procedure adjustments or design changes. Using automated dispense valves with robotic arms to dispense material onto uneven surfaces allows for the exact masking of parts with intricate geometries and irregular forms that would be difficult to mask manually with accuracy. This method can help increase throughput and decrease quality issues such as rework and scrap.

- Consistent coverage across complex shapes to support high-volume production

- Highest accuracy for placement and maskant coverage

- Programmable to accommodate multiple part configurations

Manual Application (Spray & Beads)

Even though semi- and fully-automated application methods offer great precision and increase manufacturing efficiencies, there are instances where manual masking is desired. For low-volume production where flexibility and adaptability are needed or when large surface areas require full coverage and protection, manual maskant application through high-velocity spray or beads may be warranted. Additionally, these application methods can be incorporated into existing systems to complement the process, providing some degree of automation and customization.

- Large area surfaces to be masked

- Supports low-volume production

- Manual dispense valves can be incorporated into robotic cell masking

Brushing Application

This application method is designed for low-volume, short-run, niche projects, like prototyping or components requiring touch-ups after rework. It’s important to remember that the brushing method can result in uneven masking coverage and may not be suitable when uniform, precise application is required.

- Best suited for short-run, prototype, and touch-up after repair/rework

- Difficult to achieve uniform coverage

Whether you choose an automated or manual masking method, with SpeedMask, you can apply, cure, treat, and remove the maskant in four easy steps! Additional advantages include:

- Conform to intricate configurations

- Applied by spraying or manual application

- Extra investment for design changes or new components isn’t required for material application

- After proper light cure, removal of the maskant leaves the surfaces residue-free

- Masked parts are immediately ready for production after the correct cure

- Fluorescing for quality inspection is available in some products

Contact our Application Engineering team for a consultation if you are ready to discuss your project requirements.

_________________________________________________________

Enjoying This Content? Let’s Stay Connected.

If you’re finding value in our insights, why not get more of it—delivered right to your inbox? Subscribe to receive the latest technical articles, white papers, product news, and expert tips.