Surface Treatment Options for Light-Curable Maskants in Aerospace Manufacturing

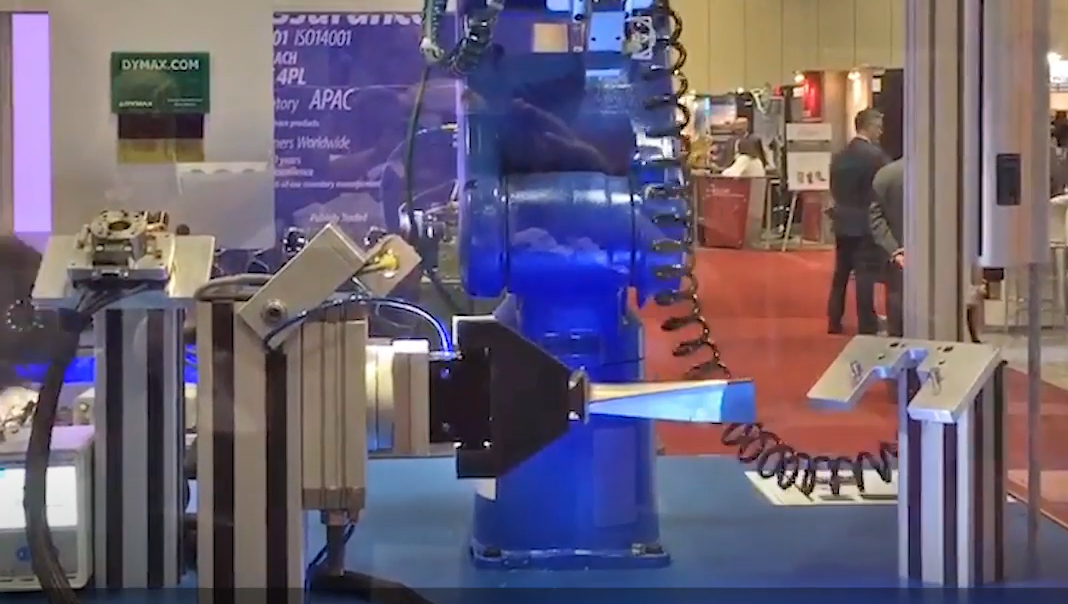

Manufacturers of critical aerospace and defense components need to reliably protect their parts when they undergo surface treatment. Light-curable maskants are an ideal product for these harsh processing methods that delicate surfaces are exposed to during these processes.

Apply, Cure, Treat, and Remove in Four Easy Steps!

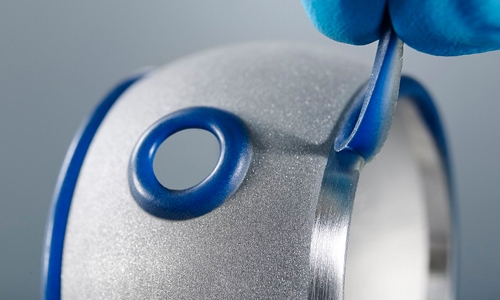

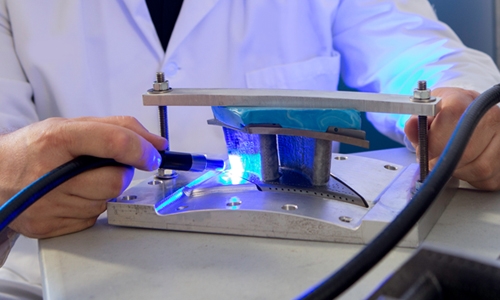

SpeedMask® masking resins provide dependable protection from thermal barrier coatings, plating, anodizing, and grit blasting processes to name a few. These one-part maskants have no solvents added and cure on demand in seconds upon exposure to UV/Visible or LED light so they are immediately ready for production. The materials dispense quickly and evenly via spray dispensing, brush dipping, or screen printing to conform to complex geometries, eliminating the labor-intensive manual application of wax, tape, lacquers, and caps and boots. Since they are flexible in application and removal, there is no additional investment required for design changes or new components. After proper exposure to light energy, the maskants are easily removed by peeling or incineration, leaving residue-free non-porous surfaces. In addition, some materials change color upon cure or have fluorescing technology for easy post-cure inspection.

Here are five kinds of surface treatment processes that Dymax SpeedMask® masking resins are well suited for:

CHEMICAL PROCESSES

- Anodizing: Protect substrate surfaces while the oxide layer of coating is applied

- Acid Stripping: Superior surface protection of nickel superalloy, steel, and titanium external and internal surfaces during chemical processing

- Chemical Milling and Etching: Cured maskants provide surface protection for selective areas or complete component protection

- Plating: Shield parts from Electroless Nickel (Ni), Platinum (Pt), Chrome (cr), Gold (Au), and Silver (Ag) plating processes

COATING PROCESSES

Resistant to the aggressive force and heat of thermal barrier coatings, cured masks absorb the energy from the force of plasma spray materials, and during painting and some e-coating and powder coating, provide superior surface component protection.

MANUFACTURING AID PROCESSES

The durability of cured resins allows maskants to be machined through, without any edge lifting of the remaining masks, while maintaining their reliable protection of surfaces. SpeedMask airflow-testing masks allow for the complete sealing of cooling holes and core cavities of turbines and components for row-by-row airflow testing.

MEDIA FINISHING PROCESSES

Three types of media finishing processes that cured masks endure well are grit blasting, shot peening, and vibratory finishing.

- Grit Blasting: Withstand exposure to aluminum oxide, garnet, plastics, and organic media

- Shot Peening: Resistant to various peening media (such as cut wire, round metal, ceramic particles, and glass beads) and the pressures used in peening applications

- Vibratory Finishing: Hold up to operations such as slurry, tumbling, or deburring to provide reliable surface protection of intricate and complex configurations

PARTS HANDLING PROCESSES

For other general masking applications, SpeedMask maskants provide superior surface protection of turbine and metal components from FOD (foreign object damage) during manufacturing, handling, and transportation.

No matter what type of surface treatment process you are involved with, there’s a Dymax masking product that’s suitable for your manufacturing.

_________________________________________________________

Enjoying This Content? Let’s Stay Connected.

If you’re finding value in our insights, why not get more of it—delivered right to your inbox? Subscribe to receive the latest technical articles, white papers, product news, and expert tips.