A case study about how a light-curable adhesive replaced a two-part epoxy for faster sensor assembly and improved the application process. ...

UV Adhesive Prevents Thermocouple Lift for Reliable Reflow Profiling

A case history exploring how adhesive bonding outperformed tape and solder in demanding reflow environments.

As printed circuit board (PCB) designs become denser and more complex, achieving accurate reflow profiling has never been more important. Temperature deviations during soldering can lead to issues such as cold joints, warpage, or component failure. To ensure consistent thermal performance, Rochester Institute of Technology (RIT) in collaboration with KIC Thermal, evaluated several thermocouple (TC) attachment methods for their impact on measurement reliability during lead-free reflow.

Through extensive multi-cycle testing, RIT found that Dymax 9037-F, a UV-curable adhesive, delivered the most accurate, repeatable, and mechanically stable results across all methods assessed.

Challenge

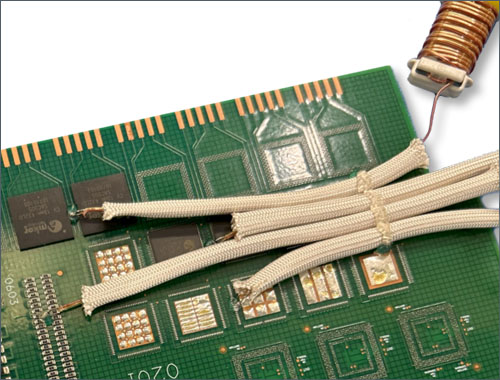

Reflow profiling depends on the quality of thermocouple attachment. Conventional methods, such as high-temperature solder, polyimide tape, and aluminum tape, each introduce process risks:

- Solder joints added thermal mass, introduced measurement lag, and sometimes cracked or detached during repeated cycles.

- Polyimide tape frequently developed air pockets, lifted during the liquidus phase, or unintentionally pulled components from their pads.

- Aluminum tape, even when framed with polyimide tape, struggled to maintain adhesion, causing component lifting on high-density boards.

These challenges prompted RIT’s research team to evaluate whether a UV-curable adhesive could provide a low-profile, stable alternative for attaching thermocouples to densely populated PCBs.

Solution

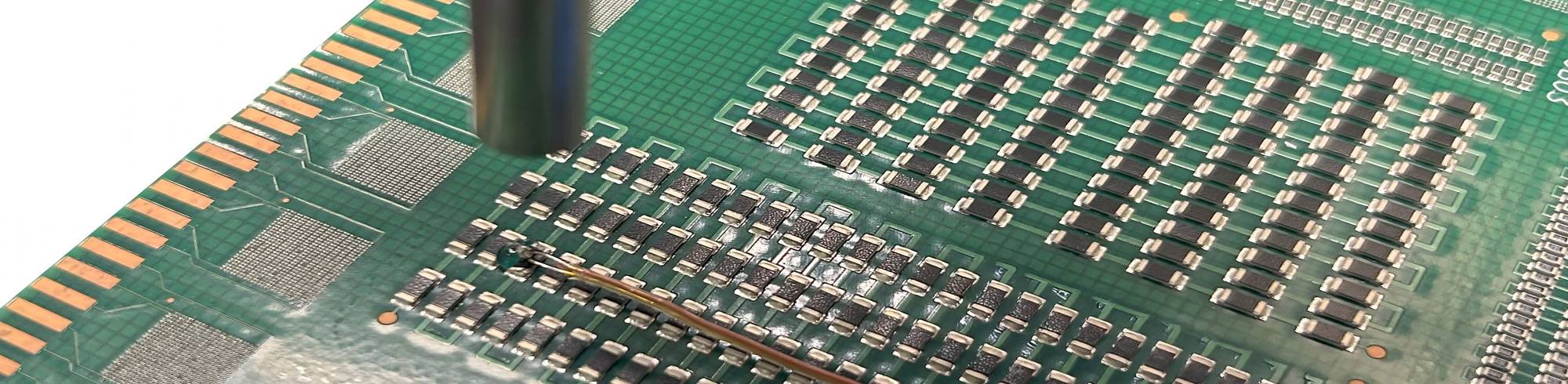

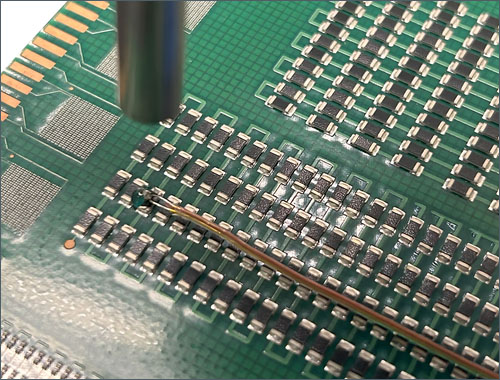

RIT performed controlled testing on identical HDI-style boards populated with components ranging from 01005 passives to QFNs and BGAs. Six thermocouples were placed on each board using various attachment methods, including three UV-curable adhesives.

Each board underwent 20 lead-free reflow cycles in a 10-zone oven, while a high-precision profiler recorded temperature data across all cycles. Post-reflow inspections evaluated bond integrity, component stability, and thermocouple placement quality.

Among the adhesives tested, Dymax 9037-F showed:

- Strong adhesion to solder mask surfaces

- Consistent bond strength through all 20 cycles

- A thin, low-mass profile ideal for accurate thermal measurement

- Clean, precise dispensing without interfering with adjacent components

Results

Exceptional Bond Integrity

Dymax 9037-F maintained a secure attachment through repeated thermal excursions without cracking, lifting, or degrading. Competing adhesives and tape-based methods required frequent rework or caused components to detach during reflow.

Reliable, Repeatable Temperature Measurements

Data collected over 20 cycles revealed highly consistent peak temperatures, staying within the thermocouple’s tolerance range. No thermal lag or measurement bias was observed, attributed to the adhesive’s minimal thermal mass and stable bond. Runs from each test day showed that once the oven reached equilibrium, temperature readings remained tightly clustered.

Simplified Process Integration

Unlike high-temperature soldering, UV application avoided thermal shock and did not require component removal. Dymax 9037-F cured within seconds under standard UV/Visible light, enabling fast, repeatable TC placement suitable for laboratory research and production environments alike.

_________________________________________________________

Download a copy of the white paper study: "Stuck on Precision: Adhesive Holds Thermocouple Tight."

*Type "thermocouple" into the Search box on the Resources Library page to access the paper.

Related Products

Check out the other Dymax products that work in conjunction with this one to create a complete solution

Product Number

Product Description

Regional Availability

Check out the other Dymax products that work in conjunction with this one to create a complete solution

More Case Studies

We offer more than products, we offer solutions. See how Dymax is helping customers solve their most challenging applications in various markets.

View allAdhesive Replaces 2-Part Epoxy for Faster Optical Sensor Assembly

Aerospace Improving PCB Conformal Coating Process

A case study on improving the PCB conformal coating process by increasing production output. ...

Aerospace Improving PCB Masking Process

A case study on improving the PCB masking process for an aerospace and defense manufacturer. ...

Aerospace Masking Process for Electroless Nickel Plating

A case study on the masking process for electroless nickel plating ...

Aerospace Printed Circuit Board Assembly

Increasing Production and Reducing Processing Time in PCB Assembly ...

Automated Masking System Revolutionizes Surface Treatment Processing

A case study about how an automated masking line drastically reduced the processing times required for an aero engine component. ...

Bonding MLAs in Automotive Headlights

Adhesive for Bonding MLAs in Automotive Headlights Exhibits Low Discoloration Under High Temperatures ...

Cinch Gaming Controllers Get Enhanced Grip

Cinch Gaming, a national leader in custom professional video game controllers, was looking for a durable solution to provide a rubber grip coating to their ABS plastic controller shells. ...

Electrical Explosion Protection & Sensor Technology

A world leader in electrical explosion protection and sensor technology was looking to turn away from laser welding for an application that requires sealing two polycarbonates of their photoelectric ...

GenZe Electric Transportation Battery Pack Gasket

Using a form-in-place gasket to create a reliable battery assembly that meets strict design standards of weight, performance, and safety. ...

High Performance Solutions for EV Charging Stations

A case study on how light-curable conformal coatings and encapsulants helped improve EV smart charging station infrastructure PCB applications. ...

Light-Curing Conveyor Enables 100% Manufacturing Scale Up

A case study on how using Dymax UVCS Light-Curing Conveyor Systems helped to increase the production of nasal swabs.VIDEO: Dymax Partners with 3D Printer Company on COVID-19 Test Swabs #InThisTogeth...

One Part, Optical Epoxy Using UV/Visible Light and Heat Cure

A case study on using ultraviolet and heat cure to secure a camera module holder to a PCB. ...

Ruggedizing Lens and Reflector Housings in Flashlights

A leading manufacturer of premium portable lighting wanted to ruggedize its safety flashlights used in the field by firefighters, police officers, and military troops. In their search for a fast-curi...

Ultra-Red Fluorescing Technology Provides Immediate Quality Check

A case study on how the use of patented Ultra-Red® fluorescing technology can aid in product verification. ...

Get In Touch

Interested in learning more or have questions? We want to hear from you.