Guidance for Selecting and Using Dymax Spot, Flood, and Conveyor Systems

Light-curing equipment selection and use often raise practical questions during process development and production. This Q&A addresses common topics related to Dymax spot, flood, and conveyor curing systems to support informed decision-making.

Q: What types of light-curing equipment does Dymax offer?

Dymax offers three main categories of light-curing systems: spot, flood, and conveyor. In addition, there are equipment accessories and radiometers to support process control and safety.

- Spot Curing Systems: High-intensity LED or UV spot lamps that deliver precise light energy to small, targeted areas and are ideal for localized adhesive or coating cures.

- Flood Curing Systems: Modular systems using UV/Visible light (e.g., metal-halide bulbs) to flood an area with curing light that are useful for curing larger surfaces or multiple parts at once.

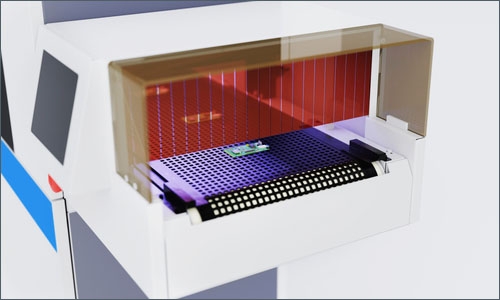

- Conveyor Systems: For high-volume or automated lines where parts pass under UV/LED flood lamps to achieve consistent, repeatable cures.

- Accessories & Radiometers: Supporting tools such as light shields, replacement bulbs, light-guides, safety eyewear, and radiometers to monitor light intensity that help ensure consistent and safe curing conditions.

Q: What are the advantages of using Dymax light-curing equipment over conventional adhesive/curing methods?

There are several advantages when combining Dymax light-curable materials (LCMs) with properly matched curing equipment:

- Speed & Efficiency: Light curing often completes in 1–30 seconds, significantly reducing cycle times, enabling faster throughput and lower “work-in-progress.”

- Process Integration & Flexibility: Systems can be used standalone (e.g., bench-top spot lamps) or integrated into automated assembly lines, giving flexibility for low-volume prototypes or high-volume manufacturing.

- Cleaner, Safer, More Environmentally Friendly: Light-curing eliminates the need for solvent-based adhesives or two-part chemistry mixing, reducing chemical handling, disposal, and regulatory burden.

- Quality & Consistency: Because Dymax develops both the LCMs and curing equipment, systems are optimized holistically, ensuring good adhesion, appropriate depth of cure, minimal shrinkage, and consistent results across batches.

Q: How do you choose which curing configuration (spot, flood, conveyor) is right for a given application?

The “right” curing configuration depends on your part geometry, volume, throughput needs, and process constraints. Consider:

- Spot systems when you need to cure small, discrete areas (e.g., bonding components, precise adhesives) with high precision or minimal heat exposure.

- Flood systems when you have larger surfaces or multiple parts that can be cured simultaneously, especially when uniform coverage is key.

- Conveyor systems when you need high throughput on production lines, especially in automotive, electronics, medical device, or other high-volume manufacturing.

To achieve a complete cure, the wavelength output of the light source should align with the photoinitiators in the material, since mismatched spectra can prevent the adhesive or coating from curing fully.

Q: What kinds of materials can be cured/bonded with Dymax equipment?

Dymax light-curing systems are compatible with a broad range of substrates, including plastics, glass, and metals.

When used with Dymax LCMs (adhesives, coatings, encapsulants, potting compounds, sealants, etc.), the equipment supports many applications: conformal coatings for electronics, adhesive bonding in optoelectronics or medical devices, encapsulation, gasketing, and more.

Q: How does Dymax ensure that its curing equipment and materials work together effectively (i.e., that a cure is “complete” and consistent)?

Several aspects ensure synergy and process reliability:

- Dymax designs both the light-curable materials and the curing equipment. This vertical integration ensures the photoinitiator chemistry and light output are well matched.

- Use of radiometers: Operators can monitor light intensity before or during production to confirm curing energy remains within the required range, helping to detect bulb degradation or shield/light-guide issues.

- Control of exposure parameters: Many spot-cure systems allow fine control over intensity and exposure time, which is important for repeatability and adapting to different materials or part geometries.

- Support from Application Engineering: Dymax offers technical support to recommend materials and curing processes for specific parts, including testing and pre-production trials to validate performance.

Q: Which industries or market segments is Dymax light-curing equipment commonly used in?

Dymax systems are used broadly across multiple markets, including automotive, electronics, medical devices, aerospace & defense, optical/telecommunications, energy, industrial infrastructure, and consumer/industrial wearables.

For example:

- In electronics: for conformal coating, encapsulation, potting, and optical display bonding of printed circuit and board-level components

- In medical: assembly, bonding, and coating of devices, such as syringes, catheters, and breathing circuits

- In industrial/energy: parts manufacturing and assembly when fast curing, bonding or sealing are important

Q: What should a manufacturer do before they commit to full-scale implementation of a light-curing system?

A best practice is to engage early with Dymax’s Application Engineers by submitting your substrate details, part geometry, required adhesives/coatings, and production throughput to the team. Dymax can then recommend suitable LCMs and light-curing equipment and often conduct testing or pre-production trials.

Also, consider running a pilot: use radiometers to confirm light intensity, test for complete cures (adhesion, strength, durability), and validate cycle times under realistic manufacturing conditions.

The combination of Dymax’s broad portfolio of light-curable materials and a full lineup of spot, flood, and conveyor curing systems gives manufacturers flexibility, speed, and quality, making light curing a competitive option for many assembly and coating scenarios across industries.

_________________________________________________________

Enjoying This Content? Let’s Stay Connected.

If you’re finding value in our insights, why not get more of it—delivered right to your inbox? Subscribe to receive the latest technical articles, white papers, product news, and expert tips.