Understanding how light-curable, low-outgassing adhesives that meet NASA and military standards provide reliability in aerospace electronics.

Electronic assemblies used in mission-critical space applications face unique material challenges that go far beyond typical manufacturing conditions. Adhesives must not only bond and protect, but they must perform reliably in extreme temperature, vibration, and vacuum environments.

This Q&A highlights the key considerations engineers should evaluate when selecting low-outgassing, low-ionic-content, light-curable adhesives for aerospace, satellite, and defense electronics, using Dymax 9773 as an example of a solution that meets critical NASA and military material standards.

What are low-outgassing adhesives, and why are they important for aerospace electronics?

Low-outgassing adhesives are formulated to minimize the release of trapped gases and volatile components that, in vacuum or low-pressure environments such as orbit, could condense on optical sensors, lenses, or PCB circuitry and degrade their performance.

NASA developed ASTM E595 to measure a material’s outgassing performance, specifying maximum limits for Total Mass Loss (TML ≤ 1.00%) and Collected Volatile Condensable Materials (CVCM ≤ 0.10%).

Adhesives that meet these limits like those listed in NASA’s MAPTIS database are trusted for spacecraft and satellite use, where optical clarity and electronic reliability are mission-critical.

What does it mean when an adhesive is MAPTIS-listed or meets NASA ASTM E595?

When an adhesive is MAPTIS-listed, it’s included in NASA’s Materials and Processes Technical Information System, confirming verified test results for TML and CVCM under ASTM E595 conditions.

This certification helps engineers quickly identify materials qualified for spacecraft or high-reliability electronic systems.

Dymax 9773, for example, appears under MAPTIS Material Code 09907, meeting both the E595 and MIL-STD-883 Method 5011 ionic cleanliness requirements, key indicators of stability and electrical reliability for space-bound electronics.

Why is low ionic content critical for circuit reliability in space and aerospace systems?

Low ionic content reduces the risk of corrosion or dendritic growth on PCB traces and solder joints, which can lead to electrical failure in mission-critical electronics.

Even trace amounts of ionic contamination—chlorides, sodium, or potassium—can attract moisture or create conductive pathways that promote corrosion or shorting.

In vacuum or low-humidity conditions, those residues become more reactive once systems cycle through temperature extremes.

Adhesives with low ionic contamination maintain electrical insulation integrity and prevent corrosion-related failure, ensuring long-term reliability for high-value systems such as avionics, defense platforms, and satellites.

How can light-curable adhesives reduce manufacturing risks and rework?

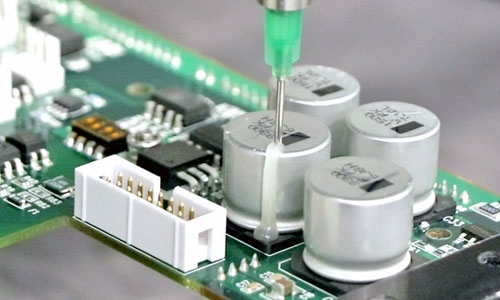

Light-curable adhesives cure rapidly on demand under UV/Visible light, allowing precise placement and immediate handling, reducing processing errors and component movement before cure.

In production environments, especially where delicate assemblies such as BGAs, CSPs, or fine-pitch components are used, engineers need adhesives that stay in place before curing and then harden instantly once positioned.

The high viscosity of Dymax 9773 adhesive allows it to remain exactly where dispensed, even on vertical or angled surfaces, with demonstrated slump resistance at 90° for up to 72 hours, until it’s cured by UV/Visible light.

This controllable cure process minimizes rework and accelerates throughput, making the adhesive ideal for PCB ruggedization, staking, or underfill alternatives used in aerospace electronics.

How can engineers determine if an adhesive is suitable for their space application?

Engineers should confirm that materials:

- Meet ASTM E595 TML/CVCM thresholds

- Are MAPTIS-listed with verified results

- Comply with low iconic content MIL-STD-883 Method 5011

These benchmarks indicate that the adhesive is appropriate for space electronics, where low contamination, electrical reliability, and mechanical stability are essential.

Dymax provides supporting data through its technical data sheets and MAPTIS entry (Code 09907) for engineers requiring qualification documentation.

Low-outgassing, low-ionic-content, and light-curable adhesives that meet NASA E595 and MIL-STD-883 Method 5011 are essential for the assembly and protection of space and aerospace electronics.

MAPTIS-listed products like Dymax 9773 provide engineers with verified options for ruggedizing, staking, underfill, and encapsulation, delivering proven performance reliability and manufacturing efficiency in vacuum and high-reliability environments.

Dymax has many light-curable solutions for critical electronics assembly that meet various approvals, including low outgassing 9771 dual-cure conformal coating.

_________________________________________________________

Enjoying This Content? Let’s Stay Connected.

If you’re finding value in our insights, why not get more of it—delivered right to your inbox? Subscribe to receive the latest technical articles, white papers, product news, and expert tips.