Standard Tests to Help Optimize Light-Curing Adhesive Performance Across Applications

Implementing a successful light-curing process requires selecting the right materials and equipment tailored to each unique bonding application. Reliable adhesives that meet industry standards help prevent failures and ensure efficient, consistent manufacturing outcomes.

For manufacturers integrating light-cure adhesives into their production processes, ensuring long-term function and reliability is paramount. Adhesives are subjected to rigorous testing to evaluate their behavior under various environmental and operational stresses to meet these performance demands.

Dymax's application engineering lab offers a wide range of testing services to help customers identify the best light-curable adhesives and equipment for their manufacturing. Our team is committed to finding the optimal solution, even if it means recommending products beyond Dymax's portfolio. We provide extensive evaluations, detailed reports, and ongoing support to ensure success throughout the entire process.

Our Services Include:

- Product and process design recommendation

- Testing and evaluation

- Pre-production trials

- Adhesive recommendations

- Cure time optimization

- Parts assembly guidance

A lab technician performs testing.

Adhesive Testing Capabilities

At Dymax, we perform various tests in our state-of-the-art laboratory, adhering to ASTM industry standards and Dymax Standard Test Methods (DSTM). We also utilize external testing labs for other analytical and application capabilities. These tests provide essential data to engineers, ensuring adhesives meet application-specific requirements. Here's an overview of some of the testing methods we offer in-house and their importance.

High-Temperature Resistance: High-temperature resistance testing evaluates an adhesive's ability to maintain its bond strength and physical properties when exposed to elevated temperatures for prolonged periods. This test is crucial for automotive, aerospace, and electronics components, where materials often encounter high-heat environments. Adhesives that fail high-temperature resistance testing are at risk of softening, weakening, or degrading, leading to potential product failures.

Why it's important: Products exposed to high operational temperatures, like engine components or electronic devices, must rely on adhesives that can withstand thermal stress. This test ensures that adhesives are minimally affected by this thermal stress, helping to support product longevity.

Corrosion Resistance: Corrosion resistance testing assesses how well an adhesive can protect bonded/coated materials from oxidative degradation, typically caused by moisture, salt, or other corrosive agents. While the adhesive may not corrode, it must shield underlying materials from exposure to these elements.

Why it's important: For manufacturers of products like marine equipment, automotive parts, or outdoor electronics, corrosion resistance is essential. Without it, bonded joints/coated surfaces may weaken over time, compromising structural integrity and leading to costly maintenance or failure in harsh environments.

An application engineer reviews testing results.

Thermal Shock Resistance: Thermal shock resistance testing exposes adhesives to sudden and extreme temperature changes, assessing their ability to maintain structural integrity without cracking, delaminating, or losing bond strength. Typically, adhesives cycle between extreme cold and hot temperatures in a short period.

Why it's important: During use, electronics, sensors, and automotive parts experience rapid temperature fluctuations. Adhesives that fail thermal shock tests can crack or delaminate, leading to electrical shorts or mechanical failures. This testing ensures adhesives can withstand real-world conditions where rapid temperature changes are inevitable.

Flame Retardancy: Flame retardancy testing determines an adhesive's ability to resist ignition or limit the spread of flames when exposed to fire. This resistance is often measured by the adhesive's self-extinguishing properties and how much smoke or toxic gases it produces during combustion.

Why it's important: Industries like aerospace and electronics require adhesives with flame-retardant properties to comply with fire safety regulations. Ensuring that adhesives pass these tests helps minimize component damage and helps products achieve necessary safety certifications.

Temperature/Humidity Resistance: Temperature/humidity resistance testing evaluates how an adhesive maintains its bond strength and stability when exposed to high humidity and high temperatures. The adhesive is placed in a controlled chamber where heat and moisture levels are cycled or sustained for extended periods.

Why it's important: Adhesives used to assemble household appliances, automotive interiors, and outdoor equipment must simultaneously withstand moisture ingress and heat. Adhesives that fail these tests may swell, weaken, or delaminate, leading to early product failure in humid climates or weather-exposed applications.

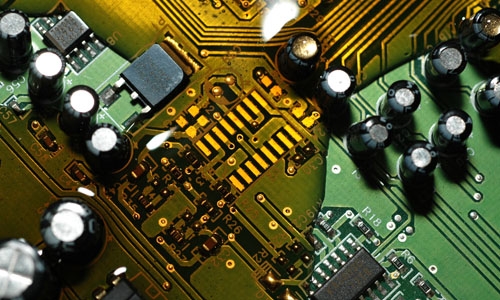

A conformal-coated PCB resists moisture ingress.

Chemical Compatibility and Resistance (for Conformal Coatings): This test evaluates how well conformal coatings resist degradation or swelling when exposed to a variety of chemicals, such as solvents, oils, cleaning agents, or industrial fluids. Samples are submerged or exposed to specific chemicals for set durations to assess any changes in adhesion, flexibility, or surface integrity.

Why it's important: Electronic devices and printed circuit boards (PCBs) require conformal coatings that can withstand exposure to chemicals used during maintenance or cleaning and endure harsh conditions without degradation to improve long-term reliability and performance.

Partnering for Success

For manufacturers, the importance of adhesive testing cannot be overstated. High temperature, corrosion, thermal shock, flame retardancy, temperature/humidity, and chemical resistance tests are all crucial for ensuring adhesives perform as expected under extreme conditions. Investing in these tests can aid with product durability, help reduce the risk of costly failures and enable compliance with industry standards.

Application Engineers discuss a customer project.

Dymax provides comprehensive testing tailored to each customer's application, offering actionable insights to guide adhesive selection and process improvement. Beyond testing, our team remains a trusted partner, providing ongoing support to ensure materials and processes align perfectly with customer needs. Contact us today to learn how we can help optimize your process.

_________________________________________________________

Enjoying This Content? Let’s Stay Connected.

If you’re finding value in our insights, why not get more of it—delivered right to your inbox? Subscribe to receive the latest technical articles, white papers, product news, and expert tips.