Key Concepts to Know About UV LED Light Curing

Many of us have had the misfortune of being exposed to the sun for extended periods, resulting in sunburn and discomfort. As a result, the light emitted by the sun has been negatively equated to the energy generated by UV-curing systems, causing people to express anxiety and even fear. Exposure to UV light has become a concern for operators using these systems in an industrial setting and individuals who utilize UV lamps to cure nail gels and coatings in salons or DIY at-home kits.

One common misconception is that light-curing UV lamps and LED (Light Emitting Diode) lamps are different and that LED lamps are safer. However, this is not necessarily the case, as both systems emit ultraviolet light in the 320-405 nm spectrum. Traditional UV lamps utilize broad-spectrum bulbs to cure via vaporization, whereas an LED is a semiconductor that generates light when an electric current runs through it. LED lamps use an array of light-emitting diodes to generate curing light.

With the proper understanding of the UV/Visible electromagnetic spectrum, how different lamps and wavelengths are used in varying capacities, and the appropriate protection protocols to implement, operators can determine the best use of curing lamps for their application to feel safe and confident while using a light-curing process.

How It All Started

UV/Visible light-curing technology has been used for over 60 years for its many benefits, especially to manufacturers who utilize it to increase assembly speeds and throughput, reduce materials costs, and devise eco-friendlier assembly processes. Historically, many components, parts, and sub-assemblies used rivets, screws, and other mechanical fasteners to join them together. With the creation of light-curable adhesives and, subsequently, light-curing lamps, this technology enabled engineers to devise manufacturing methods that created stronger bonds, enabled much faster assembly (within seconds), distributed weight and stress more evenly and provided the ability to bond dissimilar substrates while implementing a user and environmentally friendly process.

As light curing became widely accepted in manufacturing, the technology evolved from traditional broad-spectrum mercury arc and halide bulbs to LEDs. LEDs were initially integrated into dental lamps to cure photoactive restorative materials. Today they are utilized in many different capacities, from industrial curing applications and household lighting to curing UV LED nail gels.

But what is this light energy, and where does it come from? Basic knowledge of the electromagnetic spectrum and the different types of light is critical to understand how the technology works.

The Electromagnetic Spectrum and the Differences Between UVA, UVB, and UVC Ultraviolet Light

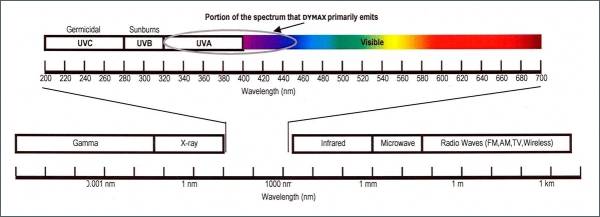

The electromagnetic spectrum is the collective term for all known frequencies and their linked wavelengths of the known photons (electromagnetic radiation). The spectrum is an extensive range of radiation that travels at the speed of light and is divided into different regions based on wavelengths that extend from radio waves (~1 m - 11 km), through visible and UV (~300-800 nm), to gamma rays (~0.001 nm). Wavelengths in these regions are commonly measured in nanometers (nm), which equate to a billionth of a meter or a thousandth of a micron.

Not all UV wavelengths are equal.

Ultraviolet light is a form of energy that occupies a small portion of the electromagnetic spectrum between X-Rays and visible light. UV occurs naturally in sunlight but is also present in many manufactured systems. UV ranges from about 200-400 nm and is divided into three regions, UVA, UVB, and UVC. The UVA range is generally considered the safest of the three.

Figure 1. Electromagnetic Spectrum

Here's an overview of the different UV wavelengths and their pros and cons.

UV-A

- 400-320 nm long wavelength

- Generally considered the safest of the UV ranges

- Accounts for 90-95% of UV radiation on Earth

- Commonly used to polymerize UV adhesives and in fluorescent inspection processes.

UV-B

- 320-280 nm medium wavelength

- A primary cause of sunburn and skin cancer

- Accounts for 5-10% of UV radiation on Earth

- Often used to cure UV inks and lacquers because UVB helps eliminate surface tack.

UV-C

- 280-200 nm short wavelength

- Most damaging UV but does not reach Earth because the atmosphere filters it out.

- Found in man-made sources like welding torches and some mercury bulbs

- Commonly used for sterilization and germicidal applications

UV Broad-Spectrum and LED Light-Curing Lamps

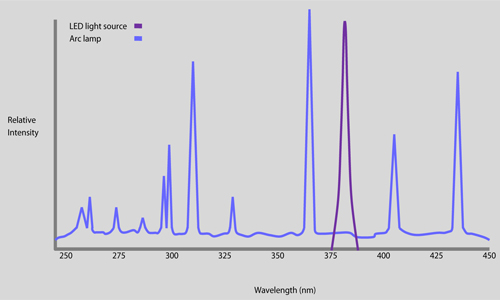

Broad-spectrum and LED are the two primary types of curing systems that utilize UVA light. The differences in the relative intensity of LED light sources have a very discrete energy wavelength versus conventional broad-spectrum arc lamps.

The first UV-curing systems used broad-spectrum lamps to cure adhesives and coatings. These conventional mercury-arc lamps are broadband light sources because they emit light over a wide range of wavelengths, including shortwave UV, longwave visible, and even longer-wave infrared, resulting in multiple energy peaks. Broad-spectrum curing systems utilize high-pressure metal-halide bulbs that produce light energy in the 300 to 450 nm range and provide 50-1,000 mW/cm2 of UVA light at the curing surface.

LED lamps generate curing energy using an array of surface-mounted LEDs instead of traditional metal halide or mercury bulbs. They are semiconductor energy sources that emit very discrete light-energy wavelengths, resulting in a single, narrow, bell-shaped emission spectrum. The wavelength distribution from a LED light source can peak in the UV or visible light range, typically at 365, 385, or 405 nm, depending upon the selection of the LED.

Figure 2. The differences in wavelength distribution between an arc lamp and an LED light source.

There are many reasons for switching from broad-spectrum curing to LED technology, including no bulbs to change and longer life (cost savings over time), no warm-up required (lamps are immediately ready for use), and they contain no mercury, like arc bulbs (less hazardous to use and dispose of).

There are inherent benefits to using both types of systems, but UV LED lamps generate cooler cures, likely leading some operators to assume they are safer. In some capacity, LED lamps are because they can cure surfaces, like nail coatings, much faster, thereby reducing the amount of UV light exposure to skin and nails. Traditional UV and LED lamps can cure polishes and nail gel coatings and are required to set nail gels and speed up regular manicures. UV lamps can take up to two minutes to cure a coating layer when curing nail gels, whereas LED lamps can cure coatings in seconds. Reduced curing time is a distinct advantage because it limits the exposure of the hands to UV light.

Limiting Exposure to UV Light

Recently, studies have re-merged regarding the effects of human cells under repeat exposure to UV-curing nail lamps and their link to potentially changing DNA structure. However, according to the FDA website, "....the FDA views nail curing lamps as low risk when used as directed...To date, the FDA has not received any reports of burns or skin cancer attributed to these lamps." UV or LED nail curing is relatively harmless when following proper safety procedures, whether someone uses the lamps in an industrial setting to bond components together or in a salon to dry-cure applied nail coatings.

In manufacturing environments, UV exposure is often misunderstood, but it is in these settings that manufacturers have the greatest control over a worker's health and safety. Industrial UV light-curing systems often have safety or engineering controls built into them. These controls, such as shielding, safety interlocks, intuitive design, and light-absorbing plastics, allow operators to use them without exposing themselves to harmful ultraviolet light.

While all UV light has the potential to harm a person when used carelessly, shortwave UV energy (UV-C) poses the most significant risk to those using these light sources. Most UV sources sold in the light-curable material and consumer markets incorporate safer UVA energy. Still, it is essential to use personal protective equipment and not to disable any safety controls designed for the UV light source. Teaching users how to protect themselves from UV exposure and training them to work safely around these UV systems will minimize any potential risk of harm. Operators should check the specifications for their UV source before using it.

When used correctly in the appropriate setting, in conjunction with personal protective equipment and training, UV broad-spectrum and LED curing lamps can be used safely for many applications.

Contact our Application Engineering team for more guidance on using UV/Visible and LED light-curing systems.

_________________________________________________________

Enjoying This Content? Let’s Stay Connected.

If you’re finding value in our insights, why not get more of it—delivered right to your inbox? Subscribe to receive the latest technical articles, white papers, product news, and expert tips.