Key Factors to Help Ensure Effective Light Curing

When it comes to selecting UV curing equipment, engineers often rely on product data sheets to compare various specifications such as intensity, curing area, and lifespan. However, one overlooked yet crucial element is the 'working distance'—the distance between the UV emitter and the substrate it's curing.

Intensity and Total Dose

Typically, the total dose of UV light required for curing is calculated by multiplying the intensity of the light by the duration of exposure.

Total Dose = Intensity × Time

Data sheets usually provide intensity measurements, helping engineers estimate the time required for the curing process. But a common oversight is the distance at which this intensity is measured.

Why Working Distance Matters

Working distance is vital as the intensity of light delivered to the substrate can differ significantly even among similar-looking emitters. The focus and divergence of the emitter also change the performance as the working distance changes. For instance, in high-speed printing, the substrate is often very close to the emitter, making focus distance less relevant. In contrast, for curing adhesives on a printed circuit board (PCB) with varying heights, an unfocused lamp may not be effective.

Case Example: Emitter A vs. Emitter B

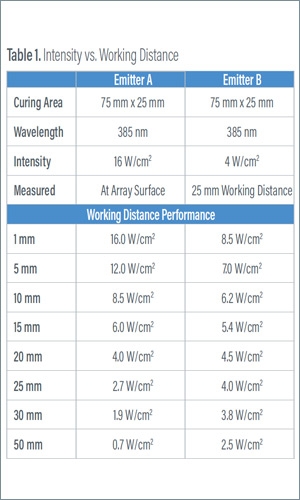

Consider two emitters with similar LED power but different focus:

- Emitter A: 16 W/cm^2, measured at the glass (unfocused)

- Emitter B: 4 W/cm^2, measured at 25 mm (focused)

Emitter A loses its intensity rapidly as the substrate moves away, making it unsuitable for substrates with varying geometries. On the other hand, Emitter B retains its effectiveness even when the substrate is 2 or 3 inches away.

Figure 3. Intensity vs. Working Distance

Uniformity and Coverage Area

Uniformity is another critical factor. Data sheets often provide a single peak intensity value, usually at the center of the curing area. However, the actual power distribution is never completely uniform across the curing area. This divergence affects curing effectiveness, especially for parts that are not centrally placed under the emitter.

The Importance of Testing

Ultimately, data sheets can only give you a part of the picture. Process engineers should conduct tests to understand how the UV curing system performs with the specific parts and formulations used. This enables accurate calculations for exposure time, ensuring a reliable and robust curing process.

In summary, when selecting UV curing systems, engineers should not solely rely on data sheet specifications. The working distance, focus, and uniformity of the emitter are key factors that require in-depth understanding and testing to ensure effective curing.

Visit our resource library to unlock the full White Paper: Comparison of Working Distance on Measured Intensity for LED Emitters

_________________________________________________________

Enjoying This Content? Let’s Stay Connected.

If you’re finding value in our insights, why not get more of it—delivered right to your inbox? Subscribe to receive the latest technical articles, white papers, product news, and expert tips.