Dymax + Tridak = Advancing Manufacturing Through Integrated Solutions

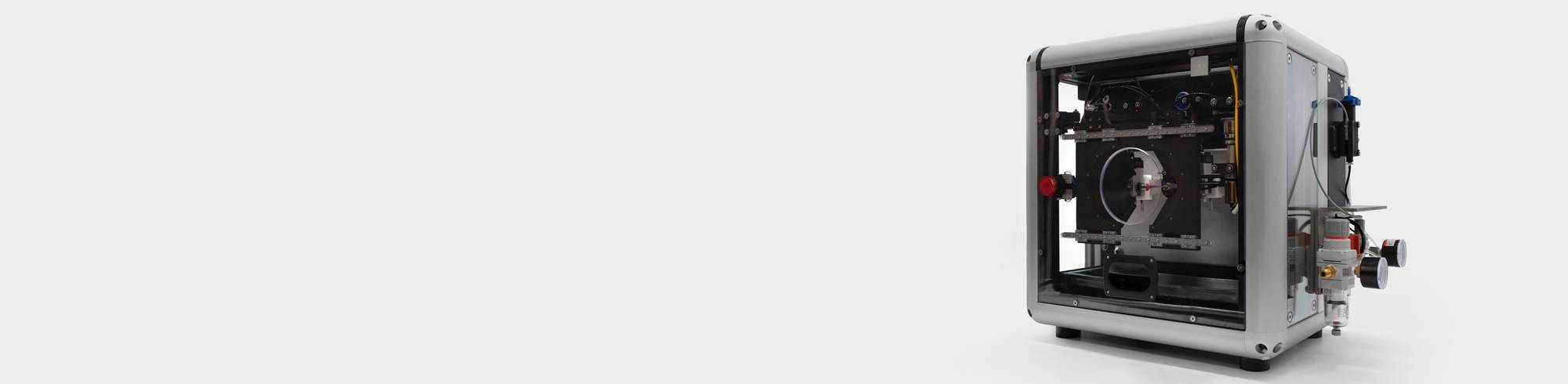

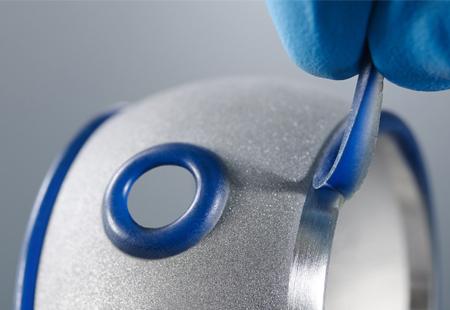

Our strategic partnership with Tridak delivers cutting-edge system integration solutions for advanced manufacturing processes. The Tridak System Integration team excels in designing automated and robotic dispensing and curing solutions tailored to diverse industries, including medical, aerospace, automotive, electronics, and packaged goods.

Comprehensive Approach

We take pride in our holistic approach to addressing manufacturing challenges:

- Concept Development: Our team collaborates with you from the initial ideation phase.

- Feasibility Testing: We rigorously evaluate the viability of proposed solutions.

- Production Design: Our experts craft efficient and scalable production processes.

Throughout each stage, we remain deeply engaged, ensuring that our products seamlessly integrate into your manufacturing ecosystem.

Trust in our expertise to optimize your manufacturing processes, increase productivity, and drive innovation in your industry. With Dymax and Tridak, you're partnering with leaders in advanced manufacturing solutions.