- Fast cure with LED or UV/Visible light

- Low temperature heat cure (80-85°C)

- Moisture resistant

- Thermal cycle resistant

- Single component

- Cold ship/Cold storage at 1-5°C

- Passes ASTM E595 Outgassing Testing

- NASA MAPTIS Listed (Material Code 09851)

Low Shrink Epoxy

9801

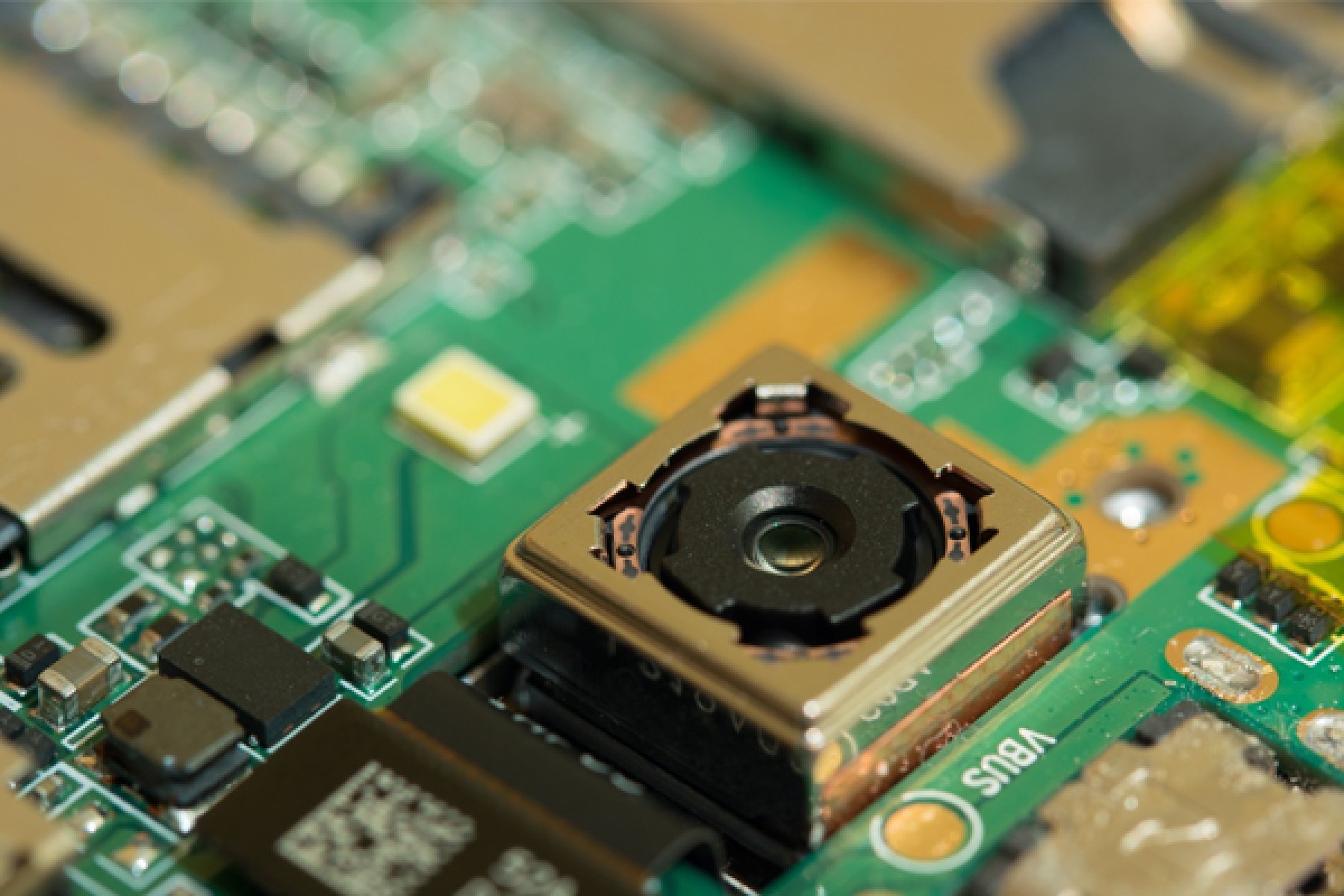

Low Shrinkage Camera Module Adhesive with LED and Heat-Cure Capability

Dymax 9801 is an LED or UV/Visible light-curable material with superior adhesion properties for bonding camera modules, lidar, active alignment applications. The adhesive is moisture and thermal cycle-resistant and meets the stringent low-shrinkage requirements introduced for active alignment applications in Advanced Driver Assistance Systems (ADAS). 9801 cures with UV light but also features heat-cure capability for applications where shadowed areas exist. It meets ASTM E595 and is NASA MAPTIS listed under Material Code 09851. This one-component product bonds rapidly and is recommended for surfaces and substrates including LCP, PCB, PPS, FPC, CAP, PS, FR-4 board, and glass.

9801 requires cold storage/cold shipping and should be kept between 1°C [34°F] and 5°C [41°F] in the original, unopened container.

Dymax materials have no solvents added and cure upon exposure to light. Their ability to cure in seconds enables faster processing, greater output, and lower processing costs. When cured with Dymax UV light curing spot lamps, focused beam lamps, flood lamps, or conveyor systems they deliver optimum speed and performance for maximum efficiency. Dymax lamps offer the optimum balance of UV and visible light for the fastest, deepest cures.

This product is in full compliance with the RoHS2 Directives 2015/863/EU.

Features

Typical Properties

Looking for additional technical specifications. Download a Product Datasheet in our Resource Library or talk with our technical experts.

Get in touch| Property | Values |

|---|---|

| Viscosity (nominal) | 60,000 |

| Uncured appearance | Off white opaque to charcoal translucent gel |

| Volumetric shrinkage | 1.5% |

| Recommended surfaces | LCP; PCB; PPS; FPC |

| Recommended substrates | CAP; PS; FR-4; Glass |

Looking for additional technical specifications. Download a Product Datasheet in our Resource Library or talk with our technical experts.

Get in touchResources

Request a Quote

Ready to take the next step? Dymax team member will get back to you shortly.

Dymax Application Engineers support all your technical requirements.

Our technical experts are ready to answer any product or application questions you may have

Find your solution