- Cures with UV/Visible light

- Multi-Cure - secondary heat cure

- True black protective coating

- Uniform matte finish

- UL 94 Flammability V-0 rating

- Designed for thin coatings

- One part formulation - no mixing

- Can be coated with multiple passes (thin or thick)

- Optimized for Single Pass Coating Up to 0.004 in

- No solvents added

Multi-Cure®

9451

True Black Conformal Coating with Secondary Heat Cure

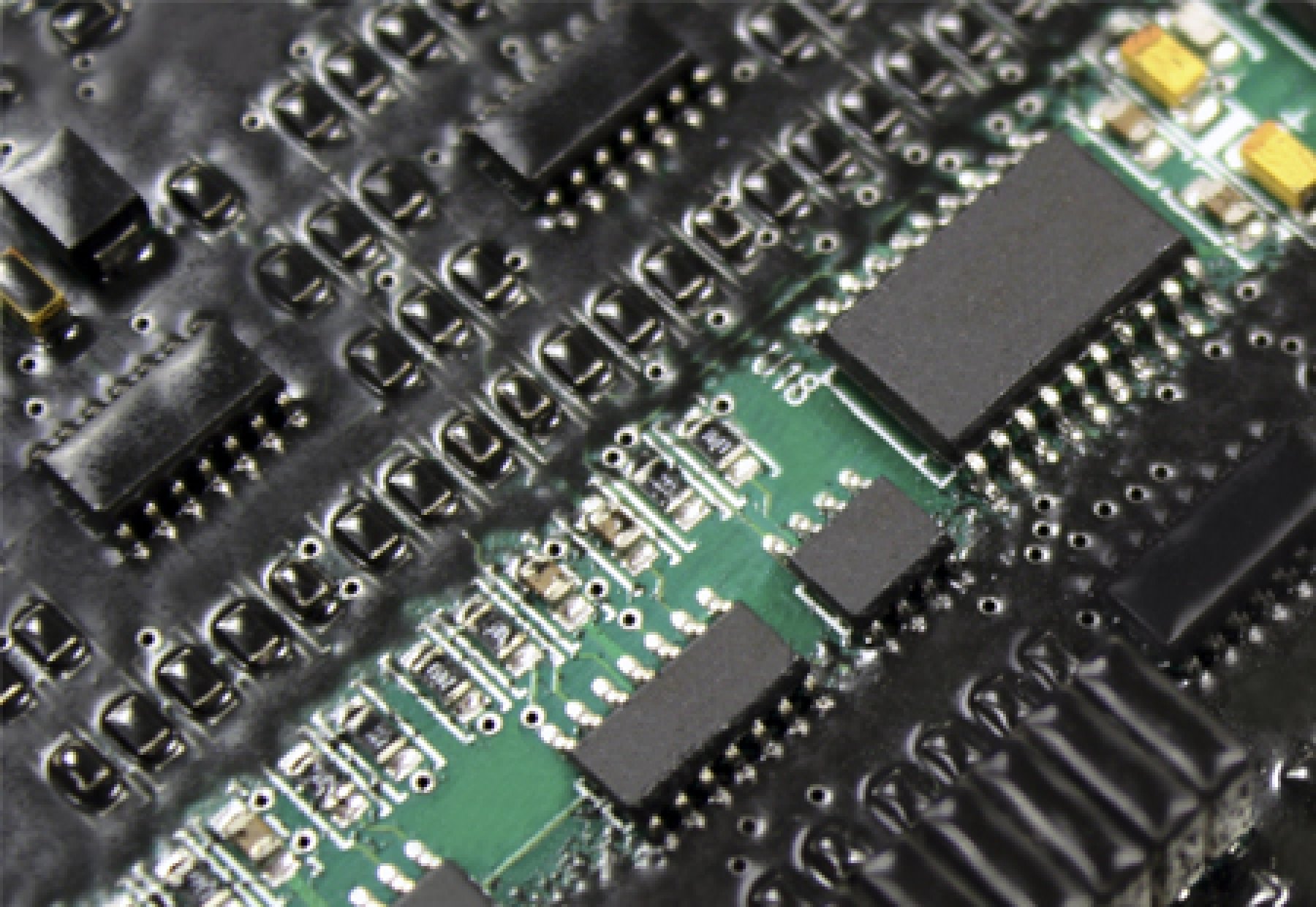

Multi-Cure® 9451 cures upon exposure to UV/Visible light for conformal coating of printed circuit boards as well as tamper-proofing. The product is a true black thin protective coating that has a secondary heat-cure capability for curing in shadow areas. It is excellent for hiding components, board features, as well as sensitive information. The material is one part so no mixing is required and it is optimized for single-pass coating up to 0.004 in.

Typical applications include conformal coating, thin protective black coating, tamper-evident coating. Recommended substrates include FR4, glass, and stainless steel.

Dymax materials have no solvents added and cure upon exposure to light. Their ability to cure in seconds results in lower processing costs. When cured with Dymax UV light curing spot lamps, focused beam lamps, flood lamps, or conveyor systems they deliver optimum speed and performance for maximum efficiency. Dymax lamps offer the optimum balance of UV and visible light for the fastest, deepest cures.

Multi-Cure® 9451 is in full compliance with the RoHS2 Directives 2015/863/EC.

Features

Typical Properties

Looking for additional technical specifications. Download a Product Datasheet in our Resource Library or talk with our technical experts.

Get in touch| Property | Values |

|---|---|

| Viscosity (nominal) | 6,000 cP |

| Cured appearance | Matte black finish |

| Fluoresces | No |

Looking for additional technical specifications. Download a Product Datasheet in our Resource Library or talk with our technical experts.

Get in touchResources

Request a Quote

Ready to take the next step? Dymax team member will get back to you shortly.

9451 Black Conformal Coating Enhances Security of Printed Circuit Boards

Dymax Application Engineers support all your technical requirements.

Our technical experts are ready to answer any product or application questions you may have

Find your solution