Dispensing Equipment

Dymax manual and automated fluid dispense systems and spray valves are easily integrated into existing manufacturing processes for easy application of coatings, lubricants, or masking resins.

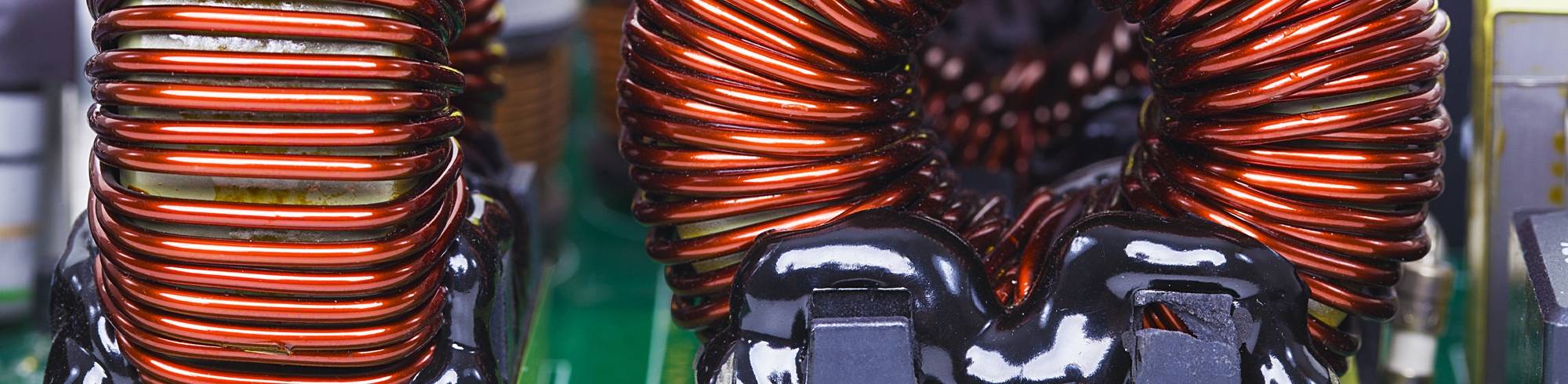

Dymax metal and structural bonding use activator-curing. Structural adhesives brought about the technology revolution known as “cold bonding”. This type of technology shortens the assembly times associated with industrial metal and glass bonding and motor and magnet assembly. The materials cure upon exposure to UV/Visible light, heat (for shadow areas), or activator (for opaque surfaces).

Adhesives bond glass, metal, plastic, ceramic, magnets, filled nylon, phenolic plastics, and polyamide, as well as dissimilar substrates. Fast cure time saves space, labor, and regulatory compliance costs making product assembly easier and more efficient for manufacturers.

Ideal for applications including:

• Metal bonding

• Coil winding

• DC motor assembly

• Magnet bonding

• Shallow potting

• Loudspeaker hardware assembly

• Automotive latches

• Consumer packaging

• Glass fixtures

• Glass furniture

Product Number

Product Description

Regional Availability

Product Number

Product Description

Regional Availability

Use our formulated product finder to help you find the right material. Interested in learning more or have questions? Contact Us, we want to hear from you.