- UV/Visible and LED (405 nm) light cure

- Multi-Cure - secondary heat-cure capability

- Low shrinkage

- Resistant to Nitric and Hydrochloric acid

- Trimmable after cure

- Sprayable

- Peelable or incineration removal

- 100% organic solids

- Compliant with with RoHS directives 2015/863/EU

SpeedMask® Masking Resin

758-H

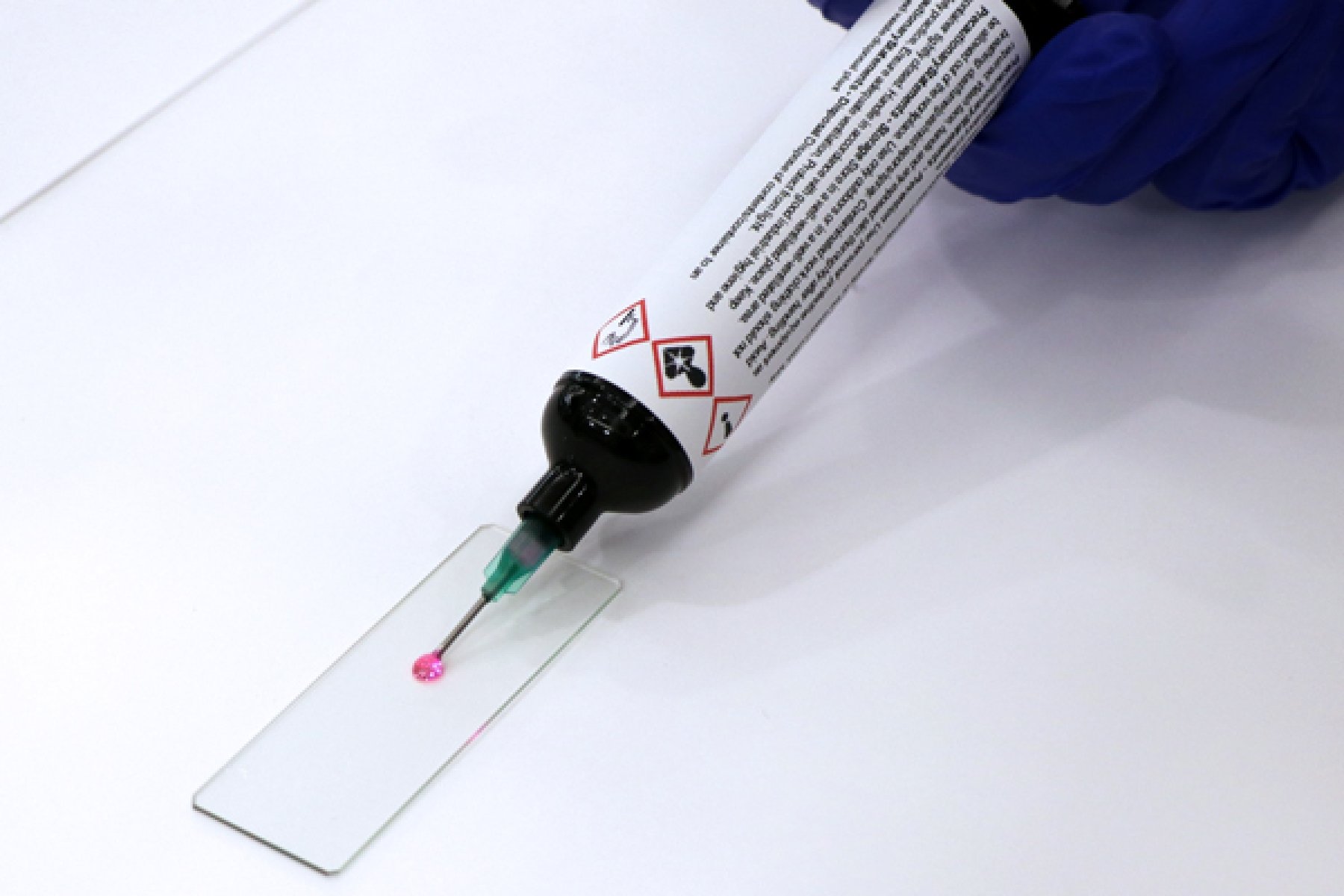

LED-Curable Acid Stripping Maskant with Secondary Heat Cure for Internal Passages

SpeedMask® 758-H maskant is formulated for UV/Visible and LED light curing to provide good protection during chemical milling/etching, plating, anodizing, and aggressive grit-blasting operations. It aids in the manufacture, overhaul, repair, and rework of turbine engine blades, vanes, and other turbine components. It is a Multi-Cure® mask specially formulated to cure with heat in applications where shadow areas exist. This 100% organic resin cures quickly and is peelable, while any internal material can be removed by incineration in an air furnace at a minimum temperature of 650°C [1200°F] leaving a residue-free surface with minimal ash from combustion of the maskant. Recommended surfaces include titanium alloys and nickel alloys.

Read how 758-H maskant was used in a PECM process to aid in the fabrication of microcutting tools.

Wali, A., Platt, T. & Biermann, D. Fabrication of microcutting tools by pulsed electrochemical machining (PECM). Prod. Eng. Res. Devel. (2025). https://doi.org/10.1007/s11740-025-01337-y

SpeedMask® resins have no solvents added and cure upon exposure to light. Their ability to cure in seconds enables faster processing, greater output, and lower processing costs. When cured with Dymax light-curing spot lamps, focused beam lamps, or flood lamps, they deliver optimum speed and performance for many masking applications. Dymax lamps offer the ideal balance of UV- and visible light for the fastest, deepest cures.

SpeedMask® 758-H is in full compliance with RoHS Directives 2015/863/EU.

Features

Typical Properties

Looking for additional technical specifications. Download a Product Datasheet in our Resource Library or talk with our technical experts.

Get in touch| Property | Values |

|---|---|

| Viscosity (nominal) | 11,500 cP |

| Shore Hardness | A80 |

| Modulus of Elasticity | 2.3 [330] MPa [psi] |

| Cure Time* | 45 sec |

| * | Cure time based upon Dymax 5000-EC Light Curing Flood Lamp System (200 mW/cm2) |

Looking for additional technical specifications. Download a Product Datasheet in our Resource Library or talk with our technical experts.

Get in touchRequest a Quote

Ready to take the next step? Dymax team member will get back to you shortly.

Dymax SpeedMask 758-H Acid Stripping Mask

Advantages of SpeedMask for Surface Protection

Dymax Application Engineers support all your technical requirements.

Our technical experts are ready to answer any product or application questions you may have

Find your solution