Understand the Differences and Applications of Various Adhesive Technologies

When selecting the best adhesive for your application, light-curable adhesives often stand out for their fast cure times, versatility, and environmental friendliness. However, each type of adhesive—whether epoxies, urethanes, silicones, hot melts, solvent-based adhesives, or cyanoacrylates—has unique properties that may make it a better choice depending on your specific requirements. Here’s a comprehensive comparison to help you choose the best product for your project.

Light-Curable Adhesives vs. One-Part Epoxies

Curing Speed: Light-curable adhesives cure in 1-30 seconds, while one-part epoxies require 5-60 minutes in a heat-curing oven.

Shelf Life and Storage: Light-curable adhesives generally offer a longer shelf life and room temperature storage, unlike epoxies, which may need refrigeration and have a shorter shelf life.

Bonding Opaque Substrates: Epoxies cure regardless of light exposure, making them ideal for opaque substrates.

Chemical Resistance: Epoxies are preferred in chemically harsh environments, while light-curable adhesives suit moderate chemical resistance needs.

Which to Choose: Light-curable adhesives for speed, ease, and longer shelf life; one-part epoxies for opaque materials and extreme chemical exposure.

Light-Curable Adhesives vs. Two-Part Epoxies

Curing and Ease of Dispense: Light-curable adhesives provide quick curing without mixing, unlike two-part epoxies that require mixing and can take up to several hours to cure.

Purge Cycles: Two-part epoxies require purge cycles that generate hazardous waste, whereas light-curable adhesives do not, making them more environmentally friendly.

Bonding Dissimilar Substrates: Light-curable adhesives bond a variety of substrates, while epoxies are generally better suited for chemically resistant applications.

Pot Life: Light-curable adhesives are one component and remain stable until light exposure, so they have no pot life, whereas two-part epoxies could have a pot life between 30-60 minutes.

Which to Choose: Light-curable adhesives for quick, clean application and minimal waste; two-part epoxies for chemical resistance and strength.

Light-Curable Adhesives vs. Cyanoacrylates

Curing Speed: Light-curable adhesives fully cure in seconds with UV light, while cyanoacrylates require only fixture hold within 10-60 seconds.

Impact Resistance: Light-curable adhesives offer options from flexible to rigid, while cyanoacrylates are generally brittle after curing.

Temperature and Moisture Resistance: Light-curable adhesives withstand greater temperature extremes and offer better moisture resistance.

Which to Choose: Light-curable adhesives for versatility and durability; cyanoacrylates for quick, no-equipment-required applications.

Light-Curable Adhesives vs. One-Part Silicones

Temperature Resistance: Silicones withstand higher temperatures, while light-curable adhesives are better for fast-paced applications needing instant handling.

Bonding Opaque Substrates: Silicones bond well with opaque substrates without light, unlike light-curable adhesives.

Worker and Environmental Safety: Light-curable adhesives do not contain isocyanates and generate minimal hazardous waste.

Which to Choose: Light-curable adhesives for rapid cure, environmental safety, and ease; silicones for high temperatures and bonding opaque substrates.

High-speed automated assembly lines are ideal for fast-curing LCMs.

Light-Curable Adhesives vs. Two-Part Urethanes

Ease of Dispense and Hazardous Waste: Light-curable adhesives require no mixing and are isocyanate-free, whereas two-part urethanes need mixing and produce hazardous waste.

Bonding Opaque Substrates: Urethanes bond opaque substrates effectively without light exposure.

Material Cost: Urethanes have a lower cost per pound, but light-curable adhesives are ideal for quick and clean application.

Pot Life: Light-curable adhesives are one component and remain stable until light exposure, so they have no pot life, whereas two-part urethanes could have a pot life between 30-60 minutes.

Which to Choose: Light-curable adhesives for ease and environmentally friendly bonding; two-part urethanes for budget-sensitive, durable applications.

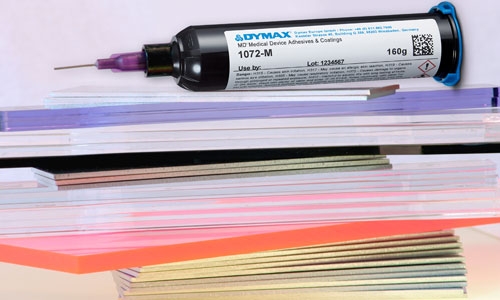

One-component materials are easily dispensed for fast processing.

Light-Curable Adhesives vs. Hot Melts

Temperature and Bond Durability: Light-curable adhesives perform well across various temperatures, while hot melts weaken at high and low temperatures.

Clarity and Bond Precision: Light-curable adhesives offer optically clear options and are available in various viscosities, unlike hot melts, which can be stringy and opaque.

Bonding Opaque Substrates: Hot melts do not rely on light curing, making them effective for opaque substrates.

Which to Choose: Light-curable adhesives for versatile, strong, and clear bonds; hot melts for opaque materials and lower-cost applications.

Light-Curable Adhesives vs. Solvent-Based Adhesives

Worker Safety and Flammability: Light-curable adhesives are non-flammable with low odor, whereas solvent-based adhesives can be highly flammable and require ventilation.

Bond Flexibility and Gap-Filling: Light-curable adhesives accommodate large gaps and bond dissimilar substrates, while solvent-based adhesives are less effective for these applications.

Which to Choose: Light-curable adhesives for safety, environmental compliance, and gap-filling; solvent-based adhesives for cost-effective, quick bonds on opaque substrates.

Light-curable adhesives are suitable for bonding dissimilar substrates.

Final Thoughts: Which Chemistry is Best?

Choosing the most suitable adhesive depends on your project’s unique demands.

Light-curable adhesives are best for projects needing fast cure times, high clarity, temperature stability, gap-filling, and environmentally friendly handling. They’re ideal in high-throughput, precision-required settings.

Alternative chemistries provide benefits that light-curable adhesives may not offer.

Epoxies and urethanes are ideal for chemically resistant, cost-sensitive, or high-temperature applications, especially with opaque substrates, and cyanoacrylates are useful for quick bonds without specialized equipment. For projects that require high-temperature stability or bonding opaque and non-heat-sensitive materials, silicones and hot melts are the better solution. Solvent-based adhesives are suitable for fast, affordable bonds where ventilation and flammability management are in place.

By understanding each adhesive’s strengths and limitations, making a decision that aligns with your application’s performance, durability, and safety requirements is much easier.

_________________________________________________________

Enjoying This Content? Let’s Stay Connected.

If you’re finding value in our insights, why not get more of it—delivered right to your inbox? Subscribe to receive the latest technical articles, white papers, product news, and expert tips.